Testing, Adjusting and Balancing Information

|

The zipfile to the left contains some resources I am happy to share with the class. But they probably should only be shared on a limited basis and not put up on a public web page because of copyrights.

| ||

- I-P_A15_Ch38.pdf is the Chapter from the ASHRAE 2015 Applications handbook on Testing, Adjusting and Balancing

- I-P_F17_Ch37.pdf is the Chapter from the ASHRAE 2017 Fundamentals handbook on Instrumentation. Of particular interest for our discussion is the section that discusses pitot tube traverses.

- NEEB Technician's Manual.pdf is my copy of the 1992 printing of the NEEB technicians manual, which is a really great reference and well worth the price of purchasing a paper copy. But I sharing this would help you out in the interim and let you see what you would be getting if you bought it. I believe it is only available as a paper copy product, probably to make it harder to proliferate on the web.

Slide Sets From the TAB Focused Webinar

These are the specific slide sets I was referencing this morning during the webinar. They are elements of the PEC classes and you will find the full classes on the PEC page of the web site if you are interested.

|

|

| ||||||

Pumps and Pumping System Supporting Information

|

The two design briefs to the left are ones I reference a lot for basics on pumps. I think you probably already reference them but just in case. In addition, the slides from the PEC Pumps class, the Chilled and Condenser Water Systems class and the Steam and Hot Water Systems class all have some content in them that might be useful; most of it would be in the Pumps class but there are case-study examples scattered through the other classes too. The latest version of all of the slides will be found on the Pacific Energy Center Classes page.

| ||||

|

The first spreadsheet looks at the technique a lot of people use for assessing savings by using a remote sensor based on research SCE did that developed different coefficients (less than 3) that you would apply to the pump power affinity law to project savings. It is an accepted metric but what bothered me about it was that it projects 0 kW at 0 gpm and from field testing, we know that is not true when you deadhead a pump.

That means that you could use an approved metric to project savings and then not achieve it when they came to do the M&V because the approved metric would overstate savings at part load. So, if your load profile has a lot of part load hours - and West Coast/PNW load profiles seem to - then you could be in trouble. That is what cause me to come up with the technique in the PowerPoint presentation file. The two spreadsheets below it are the calculations behind the graphs in the presentation; Case 1 is controlling for remote DP and Case 2 is controlling for the header DP. | ||||||||

|

The zipfile to the left has all the other files associated with applying the calculation technique I discuss above to the chilled water plant in the model. The READ ME file describes everything in the zip file. But it kind of ties all of this stuff together by:

| ||||

One of the options involves adding a more efficient distribution pump because it turns out the existing pumps were best first cost but about 10% less efficient than the best life cycle cost pump. What's kind of interesting is that doing trim and respond (basically the best possible savings you can get) with the existing pump saves as much or more energy than adding a more efficient pump but using a remote sensor to control it.

That implies that if you added the new pump and did trim and respond with it, you would save the most energy. But the control system would need to be able to support the network traffic required to do that. In the model, the control system could support it. So potentially, you would save the most energy by adding the pump and doing trim and respond and it would be a viable project for a long term Owner.

But in terms of "bang for the buck", you could get almost as much savings by optimizing the existing pump with a trim and respond strategy, which would leave a pile of money that you could use for an additional ECM. Of course that would change if the Owner was going to add a pump anyway for redundancy purposes.

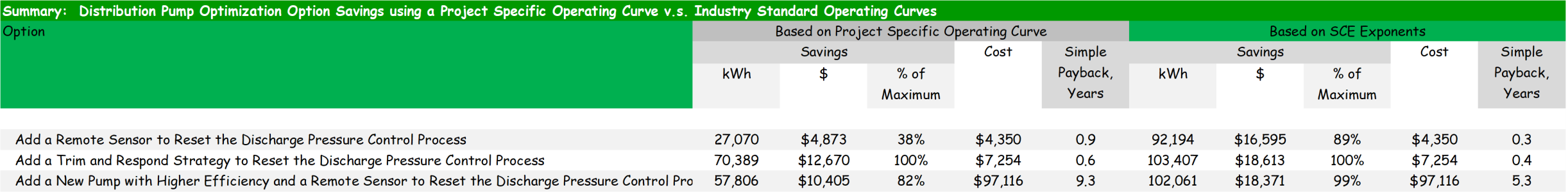

The table below is the summary for the example.

That implies that if you added the new pump and did trim and respond with it, you would save the most energy. But the control system would need to be able to support the network traffic required to do that. In the model, the control system could support it. So potentially, you would save the most energy by adding the pump and doing trim and respond and it would be a viable project for a long term Owner.

But in terms of "bang for the buck", you could get almost as much savings by optimizing the existing pump with a trim and respond strategy, which would leave a pile of money that you could use for an additional ECM. Of course that would change if the Owner was going to add a pump anyway for redundancy purposes.

The table below is the summary for the example.

|

The two presentations to the left are ones I use to explain why two pumps (or fans) - each rated for design flow, piped in parallel and serving a common distribution system - running at less than rated speed will not save energy compared to running one pump by itself. The converse is also demonstrated by implication; i.e. why, for instance, two independent cooling tower cells running at 50% speed will use much less energy than one cell running at full speed. I am on the verge of putting up a blog post that covers this.

| ||||

|

This is a set of slides I use at U of W DDC class that touches on some of the other topics. But there is a case study regarding a large condenser water system where the interaction of the pumps causes operating problems and also provides energy savings opportunities if you added VFDs and controls, so that is why I included it. You can feel free to use on your website and classes, but it but it would be best to import it into a different template to get rid of the U of W logo since folks pay to take that class.

| ||

Scope of Work Documents Example

These are the example documents mentioned in the Scope of Work presentation. They are targeted at adding a new redundant evaporator pump to the Hijend Hotel central chilled water plant. I have also included a version of the SketchUp model that shows what the installed pump would look like as well as the itemized take off behind the price for installing the pump to give you a sense of what goes into that.

|

| ||||||||||||

Boiler Scope of Work Materials

These are the materials for the class today.

|

| ||||||||