Monitoring Plan Spreadsheet

Monitoring plans are important tools for organizing your data logging and data gathering effort on a commissioning project. This page includes a number of resources to help you develop a monitoring plan.

Monitoring Plan Template

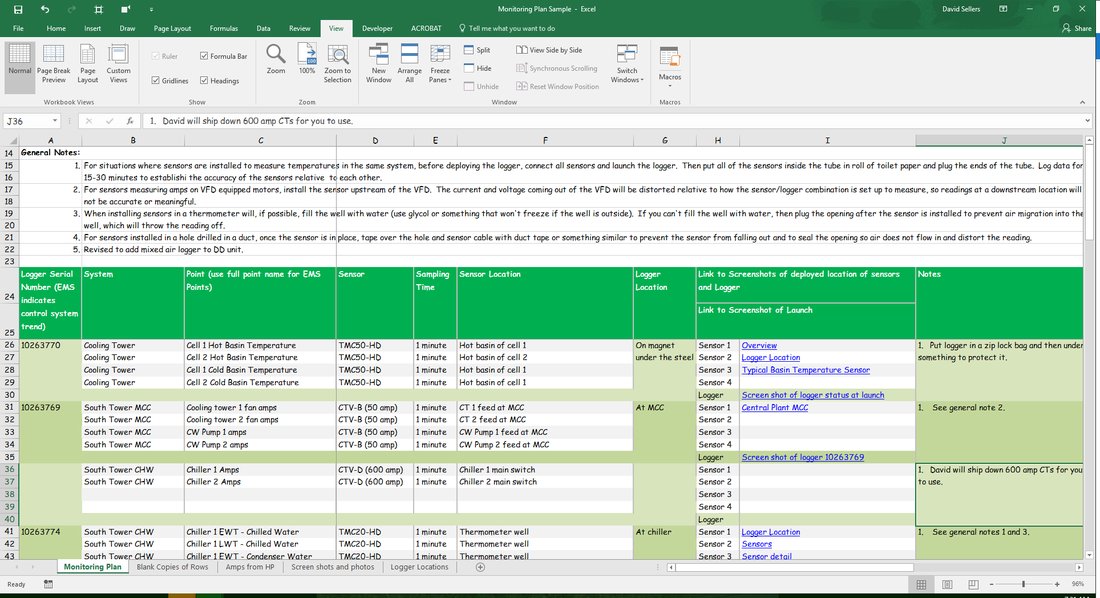

Monitoring plans are important tools for organizing your data logging and data gathering effort on a commissioning project. At a minimum, they can help you think through exactly what you need to monitor and how you will go about doing it for the system or systems you are studying by documenting the list of data points and sensors you will require along with the necessary sampling frequency.

And if you want to get fancy, you can group the sensors by the logger they will be associated with and include items like the data logger serial number, the location where the logger is to be deployed, and details of how you want to install the sensors. You can even provide a link to a screen shot of the logger software launch information and a picture of the installed logger. On large projects, these details can make it a lot easier for you to remember exactly where the loggers are when it comes time to pull them back in and facilitate having others work with you to deploy and retrieve them.

The links below will take you to a black copy of the spreadsheet I use as a monitoring plan and also a copy of the spreadsheet after it was filled out for a project a while back. If you are looking for a bit more of a discussion on how to go about deciding what to monitor, you may find the video below to be helpful as well as a string of blog posts I wrote regarding how I went about logging a heating hot water system.

And if you want to get fancy, you can group the sensors by the logger they will be associated with and include items like the data logger serial number, the location where the logger is to be deployed, and details of how you want to install the sensors. You can even provide a link to a screen shot of the logger software launch information and a picture of the installed logger. On large projects, these details can make it a lot easier for you to remember exactly where the loggers are when it comes time to pull them back in and facilitate having others work with you to deploy and retrieve them.

The links below will take you to a black copy of the spreadsheet I use as a monitoring plan and also a copy of the spreadsheet after it was filled out for a project a while back. If you are looking for a bit more of a discussion on how to go about deciding what to monitor, you may find the video below to be helpful as well as a string of blog posts I wrote regarding how I went about logging a heating hot water system.

|

| ||||

Point List Resources

Monitoring plans and the point lists used to specify the points required by a control system when it is designed are very similar. Thus, you may find the following point list resources to be helpful to you as you develop your monitoring plan. This blog post will also provide some insight on the topic.

Control Design Guide

The Functional Testing Guide included a Control Design Guide as part of the package. The Control design guide provides information about different sensing technologies and how to select the most appropriate technology. It also included a point list tool. You can find out more about the Functional Testing Guide at this link and details about the Control Design guide at this link. You can download a copy of the package from the Functional Testing Guide page of the website.

Control Spec Builder

In an effort to "level the playing field", Automated Logic Corporation developed a product called Control Spec Builder. The tool allows you to put a control system design together, including specification language, point lists, system diagrams, and narrative sequences of operation and then export it to a Word Document. Thus, you may find the point list component to be useful in terms of helping you understand what points you might want to include in your monitoring plan.

While you may be suspicious of a vendor developed tool for something like this, in my experience, this tool is non-proprietary and you could actually edit ALC out of the spec you built with it and end up with an ASHRAE Guideline 13 based specification.

A Guide for Specifying Performance Monitoring Systems in Commercial and Institutional Buildings

Pacific Gas and Electric, in conjunction with the Lawrence Berkeley National Laboratory developed a guide specification in 2006 that has a lot of useful information about how to specify performance monitoring systems.

Control Design Guide

The Functional Testing Guide included a Control Design Guide as part of the package. The Control design guide provides information about different sensing technologies and how to select the most appropriate technology. It also included a point list tool. You can find out more about the Functional Testing Guide at this link and details about the Control Design guide at this link. You can download a copy of the package from the Functional Testing Guide page of the website.

Control Spec Builder

In an effort to "level the playing field", Automated Logic Corporation developed a product called Control Spec Builder. The tool allows you to put a control system design together, including specification language, point lists, system diagrams, and narrative sequences of operation and then export it to a Word Document. Thus, you may find the point list component to be useful in terms of helping you understand what points you might want to include in your monitoring plan.

While you may be suspicious of a vendor developed tool for something like this, in my experience, this tool is non-proprietary and you could actually edit ALC out of the spec you built with it and end up with an ASHRAE Guideline 13 based specification.

A Guide for Specifying Performance Monitoring Systems in Commercial and Institutional Buildings

Pacific Gas and Electric, in conjunction with the Lawrence Berkeley National Laboratory developed a guide specification in 2006 that has a lot of useful information about how to specify performance monitoring systems.

|

Since the physical principles have not changed, the guidance is still timely. You will find a paper about the guideline (which is very useful in and of itself) on the LBNL Energy Technologies site at this link. The file to the right is a copy of the actual guide specification.

|

| ||