Circular Equivalent of a Duct and Equivalent Diameter

Most of the duct friction charts that are out there are based on round ducts. That means that if you are working with a rectangular duct or a flat oval duct, you will need to come up with the equivalent circular duct size if you are using some other cross sectional shape, like rectangular duct or flat oval duct. The terms Circular Equivalent of a Duct and Equivalent Diameter sound like the same thing, but technically, there are two different concepts with different formulas for calculating them.

The circular equivalent of a duct formulas are published by ASHRAE and are used to compare different shaped ducts in terms of their air handling capacity and to allow you to use a duct friction chart that is based on round duct for other duct shapes. The equivalent diameter formula is published by AMCA and is used to determine effective duct length.

The circular equivalent of a duct formulas are published by ASHRAE and are used to compare different shaped ducts in terms of their air handling capacity and to allow you to use a duct friction chart that is based on round duct for other duct shapes. The equivalent diameter formula is published by AMCA and is used to determine effective duct length.

Why Different Duct Shape?

ou may be wondering why ducts come in different shapes in the first place. If there is no constraint on space, then, for a given volume of air at a given friction rate, round duct will probably be the best choice for a number of reasons including:

An interesting aspect of the fact that a higher aspect ratio duct requires a larger cross-section to deliver a given flow rate at a given friction rate is that the velocity in the high aspect ratio ducts will be lower than they would be for a square or round duct carrying the same flow at the same friction rate. Since the pressure drop through a duct fitting is a function of the velocity pressure and the velocity pressure is a function of the square of the velocity, the preceding implies that a poor fitting design will be a bigger problem in a round duct or square duct compared to the same fitting design applied in a higher aspect ratio duct sized for the same air flow and friction rate.

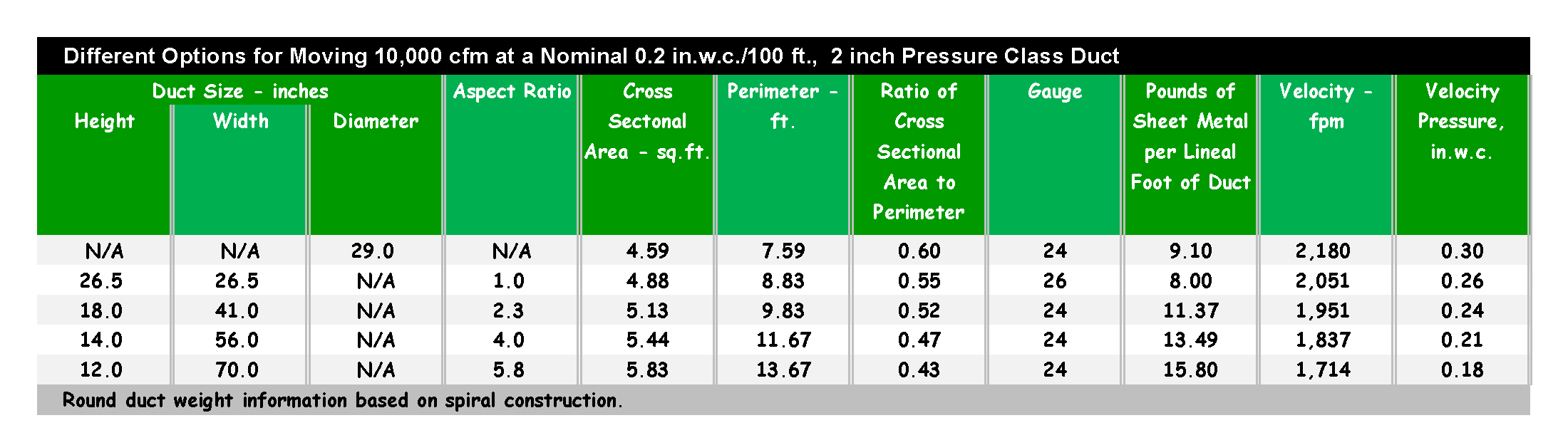

The table below illustrates some of the points made above.

- Less weight, which has both a structural and a cost implication.

- Less perimeter, which means insulating costs will be lower and the surface are for heat transfer to occur through is smaller.

- Less low frequency break-out noise; i.e. rectangular ducts are more likely to rumble.

An interesting aspect of the fact that a higher aspect ratio duct requires a larger cross-section to deliver a given flow rate at a given friction rate is that the velocity in the high aspect ratio ducts will be lower than they would be for a square or round duct carrying the same flow at the same friction rate. Since the pressure drop through a duct fitting is a function of the velocity pressure and the velocity pressure is a function of the square of the velocity, the preceding implies that a poor fitting design will be a bigger problem in a round duct or square duct compared to the same fitting design applied in a higher aspect ratio duct sized for the same air flow and friction rate.

The table below illustrates some of the points made above.

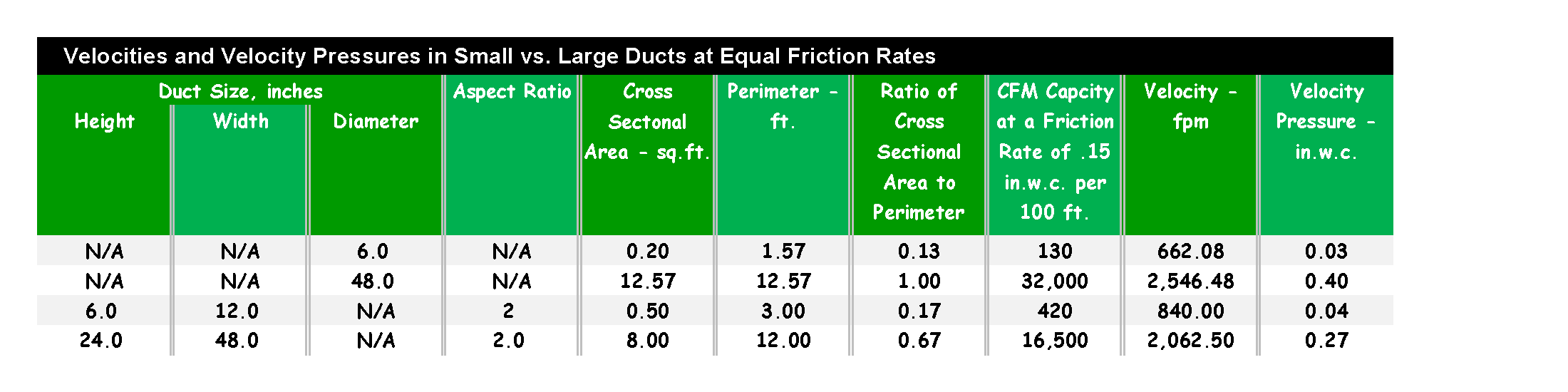

As duct sizes increase, the number of square inches encompassed by each inch of perimeter also increases. That implies that for a given friction rate, large ducts will have much higher velocities (and thus, operate at much higher velocity pressures) than small ducts. This in turn implies that a poor fitting design in a large duct can be a much more significant problem than an identical poor fitting design in a small duct because the loss through a fitting is a function of the velocity pressure, which in turn, is a function of the square of the velocity.

The table below illustrates this phenomenon.

The table below illustrates this phenomenon.

Circular Equivalent of a Duct

Rectangular Ducts

ASHRAE defines this as the diameter of a rectangular duct that has equal resistance to flow for an equal flow rate and length. It is not the same thing as the AMCA term Equivalent Duct, which will be discussed in the next section.

Flat-Oval Ducts

ASHRAE also publishes a formula for calculating the circular equivalent of a flat-oval duct.

Equivalent Diameter

AMCA Standard 201 defines the term equivalent duct diameter as the diameter of a circle having the same cross sectional area as another geometric shape. In other words, the AMCA equivalency term is focused on a dimensional equivalency where-as the ASHRAE equivalency term is focused on air handling equivalency. Thus, the terms represent two different concepts and the results of the formulas can not be use interchangeably.

Resources

The downloads below will give you to the .wmf files that are discussed above so you can use them to document your math in a spreadsheet, report, or presentation. You may also find the following related information on the website to be helpful:

- Hydraulic diameter is a concept that is similar but not identical to the circular equivalent of a duct size and is discussed on the Hydraulic Diameter page of the website.

- The Effective Duct Length spreadsheet tool has the equations for 100% effective duct length, circular equivalent duct size, equivalent diameter, and hydraulic diameter built into it to allow you to enter a flow rate and your duct dimensions and calculate the various metrics.