Vintage 1968 Carrier Design Manual

These days, there sometimes seems to be a tendency to set aside anything that is more than a couple of years old as being irrelevant and dated. Of course, that is coming from an older guy like me, who is probably worried that he may becoming irrelevant and dated.

But still, given that our buildings and their systems will have significantly longer life cycles than a couple of years, and given the nature of physics, concepts and configurations that are more than a few years old can still be relevant, especially if you need to work with one in an existing building. Frequently, I find myself working with a system that was designed years ago using the prevailing design philosophy of the time, like this 1949 or so vintage double duct system that is still very much in service down in the Bay area.

But still, given that our buildings and their systems will have significantly longer life cycles than a couple of years, and given the nature of physics, concepts and configurations that are more than a few years old can still be relevant, especially if you need to work with one in an existing building. Frequently, I find myself working with a system that was designed years ago using the prevailing design philosophy of the time, like this 1949 or so vintage double duct system that is still very much in service down in the Bay area.

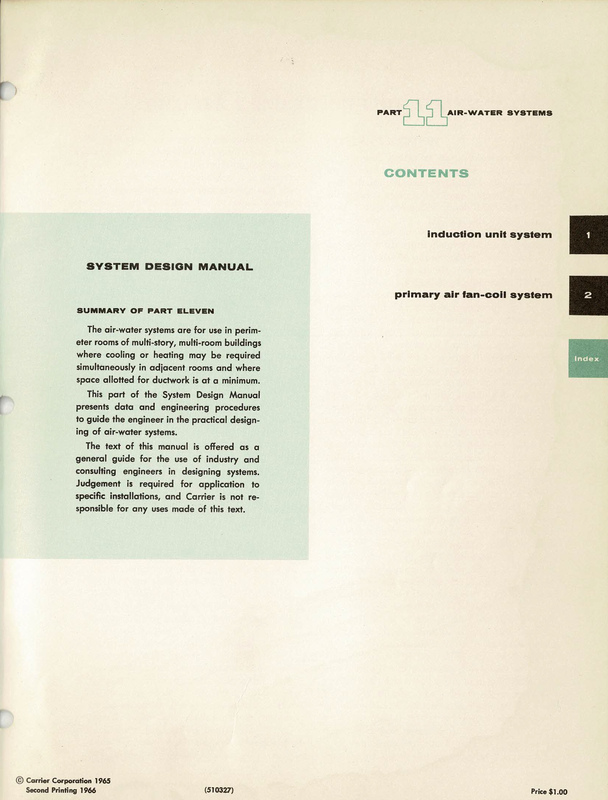

High velocity induction systems are another common example. Just about every year I have taught the Existing Building Commissioning Workshop series with Ryan Stroupe down at the Pacific Energy Center, there has been at least one student who had a building with one of these system types in it, and this year has been no exception.

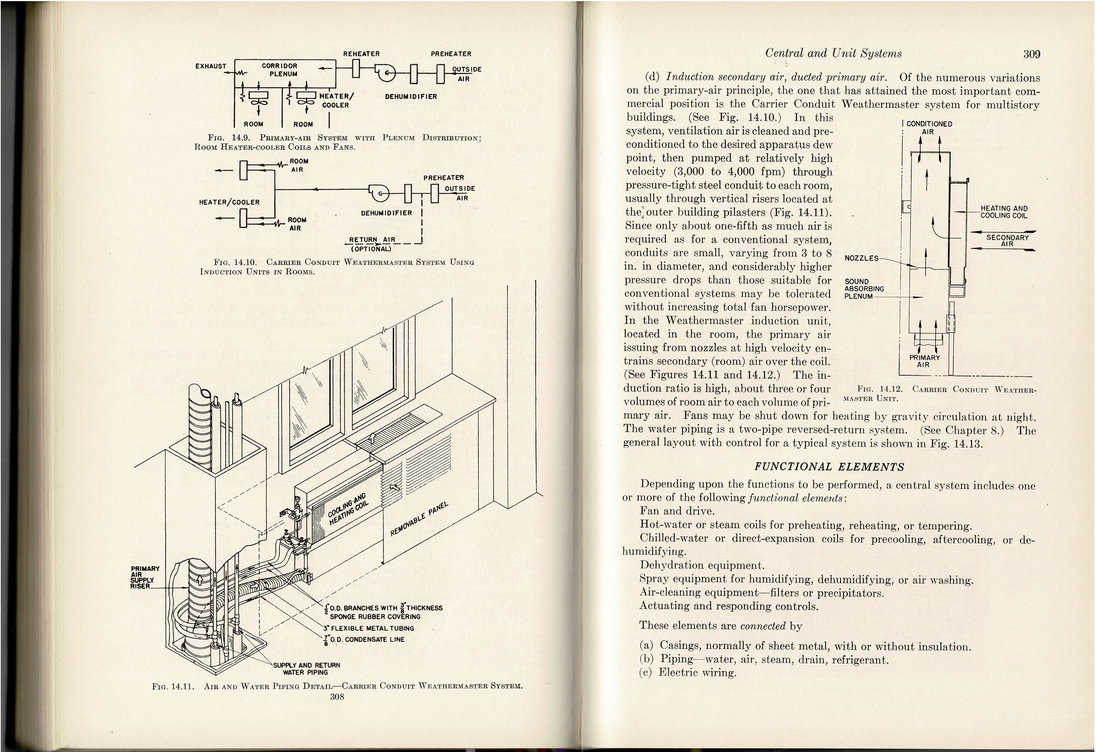

I first encountered this system type the first year of my career, when Bill Coad sent me down to work on the Executive Office Building, a 1960's vintage high rise in downtown St. Louis.

I first encountered this system type the first year of my career, when Bill Coad sent me down to work on the Executive Office Building, a 1960's vintage high rise in downtown St. Louis.

|

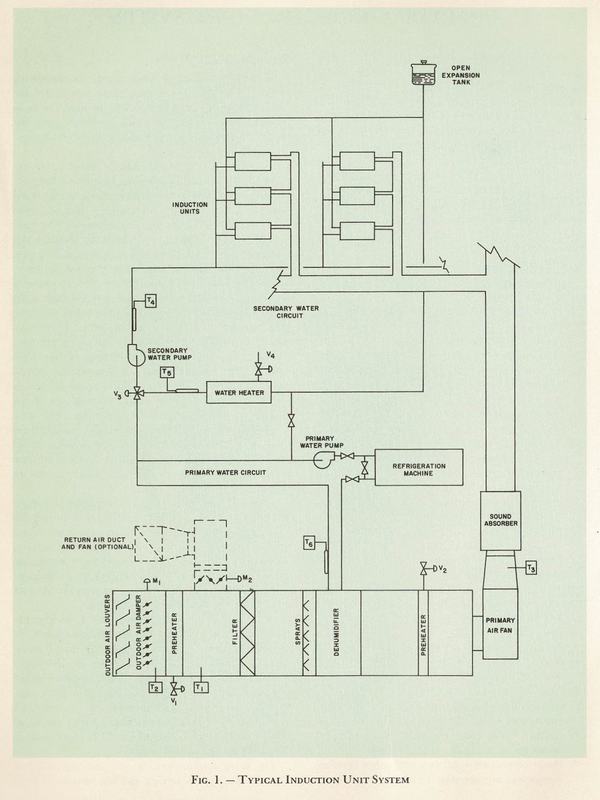

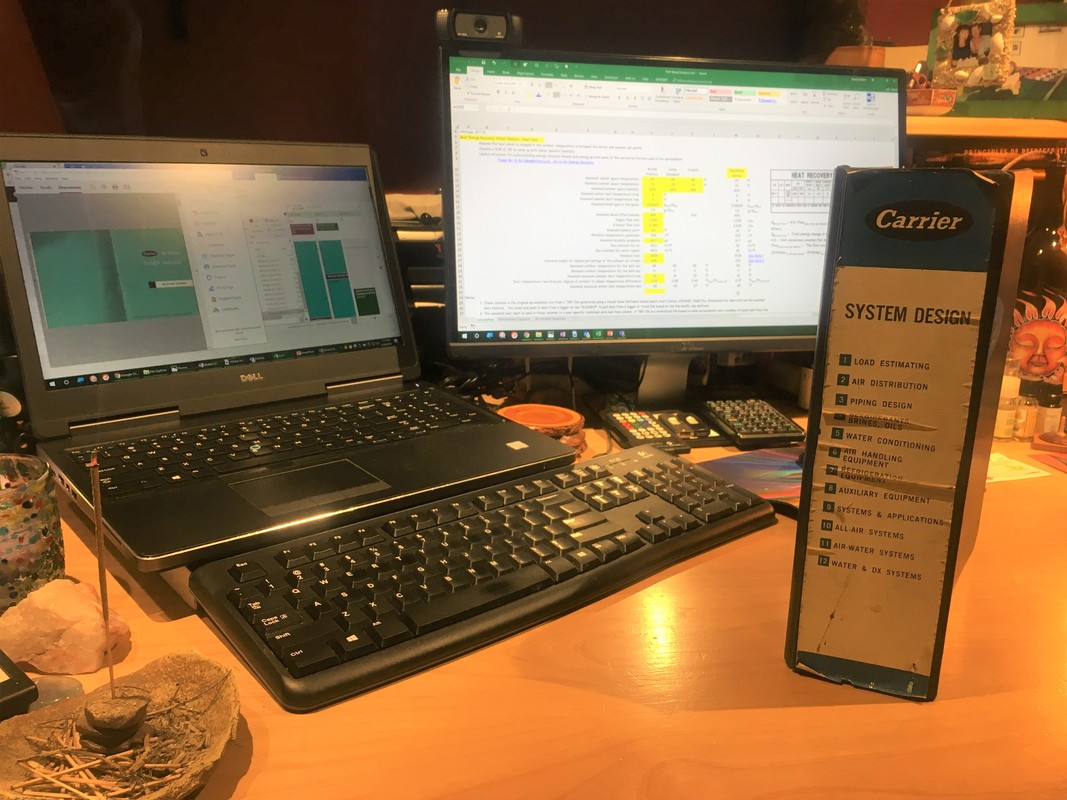

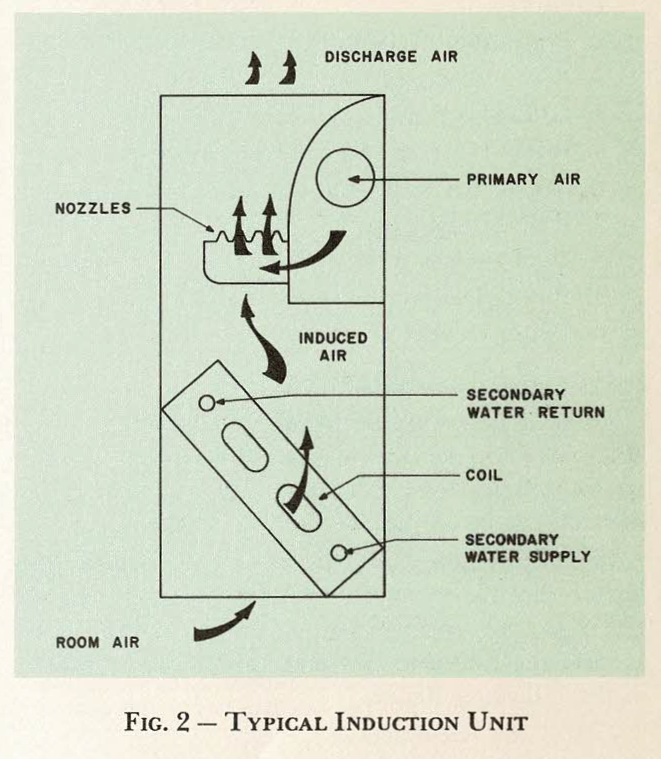

Back then, one of my main resources for understanding those systems was the Carrier Design Manual. The copy I have was generously shared and then given to me by Bud Wiecezorik, who spent many hours mentoring me out in the field about this new world I found myself adopting as a career. The image below, taken from one of the chapters in the manual, illustrates the system configuration.

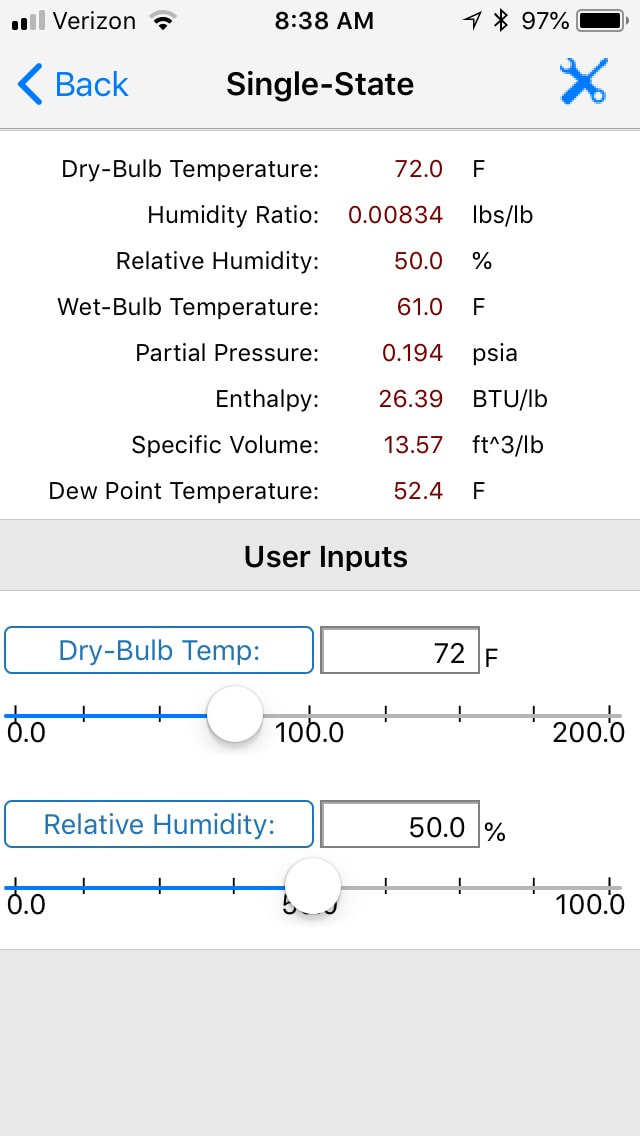

On the air side, the design approach distributed air to terminal units which, in the case of the system I was working in in 1976, were located along the perimeter of each floor in the building. The terminal units contained a primary air manifold with nozzels attached to it, as can be seen from the images to the right. The primary air jetting through the nozzels induced air flow from the space across a water coil, which could have hot or chilled water in it.

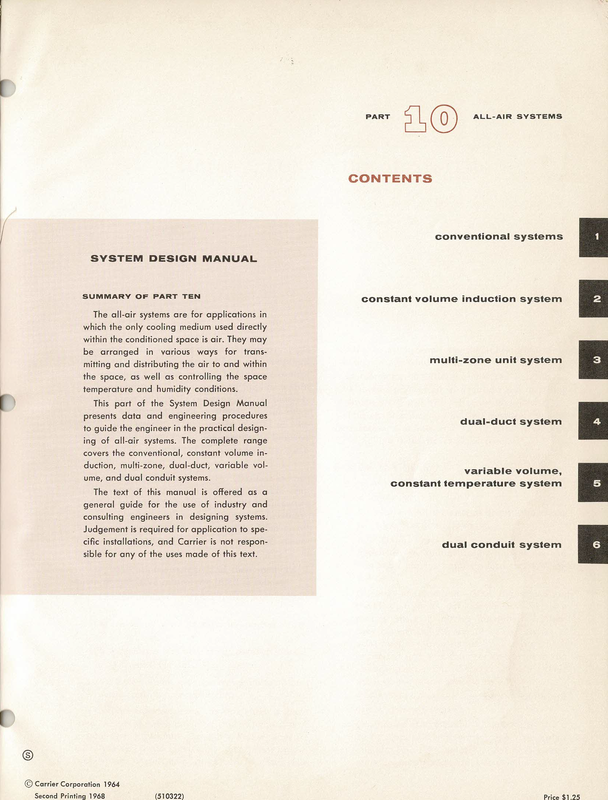

Temperature control was achieved by varying the primary air temperature, the water temperature and by modulating the air flow around the coil with a damper of the water flow through the coil with a valve. The system was very flexible because you could use warm air and warm water, cold air and warm water, warm air and cold water, or cold air and cold water depending on the nature of the load and the current operating status of the utility systems in the central plant. The Executive Office Building had separate systems for each face of the building and on a sunny winter day, it was not inconceivable that you would be using cold air and warm water on the south face to address the solar load with warm air and warm water on the North face since it received no direct sunlight and thus, there was a net energy loss from the zone due to transmission and infiltration on that side of the building. My point in bringing this up here is that it turns out my "out dated" 1964 edition of the Carrier Design Manual is actually kind of handy to have if you find yourself working with these systems, as is the case for two of the students in the EBCx class this year. So I decided to make a page on the web site where I could place scans of the various chapters in the manual so they were available for reference to those working with these systems in existing buildings. I will start with the chapters that are the most relevant to the needs of my current students, those being the chapters about induction systems like the one I have illustrated above. But eventually, I hope to get the entire manual scanned and posted. It will just take a while since the chapters are bound and it is a manual, page by page process to make the scans since I don't want to cut the binding. |