ValvesValves are the gate keepers in our piping systems, controlling the flow through them in a number of ways. While some of the ones you may encounter out in the field may be totally unfamiliar to you, most of us use valves every day at home. For example, the faucet on your kitchen sink is a type of valve.

There are many, many different types of valves, classified primarily by their physical features (gate valve, check valve, etc.) and/or their function (service valve, check valve, etc.). As a result, the gallery in this section of the website is subdivided by those classifications to organize it a bit more. To use the gallery, scroll down until you find something that looks like what you saw out in the field. If you don't find what you are looking for, feel free to submit a picture of what you saw and we will see if one of the folks on our team can identify it and then add it to the appropriate gallery if it is something new. Use the navigation tabs at the top of the page to get back to the home page or a different part of the web site. |

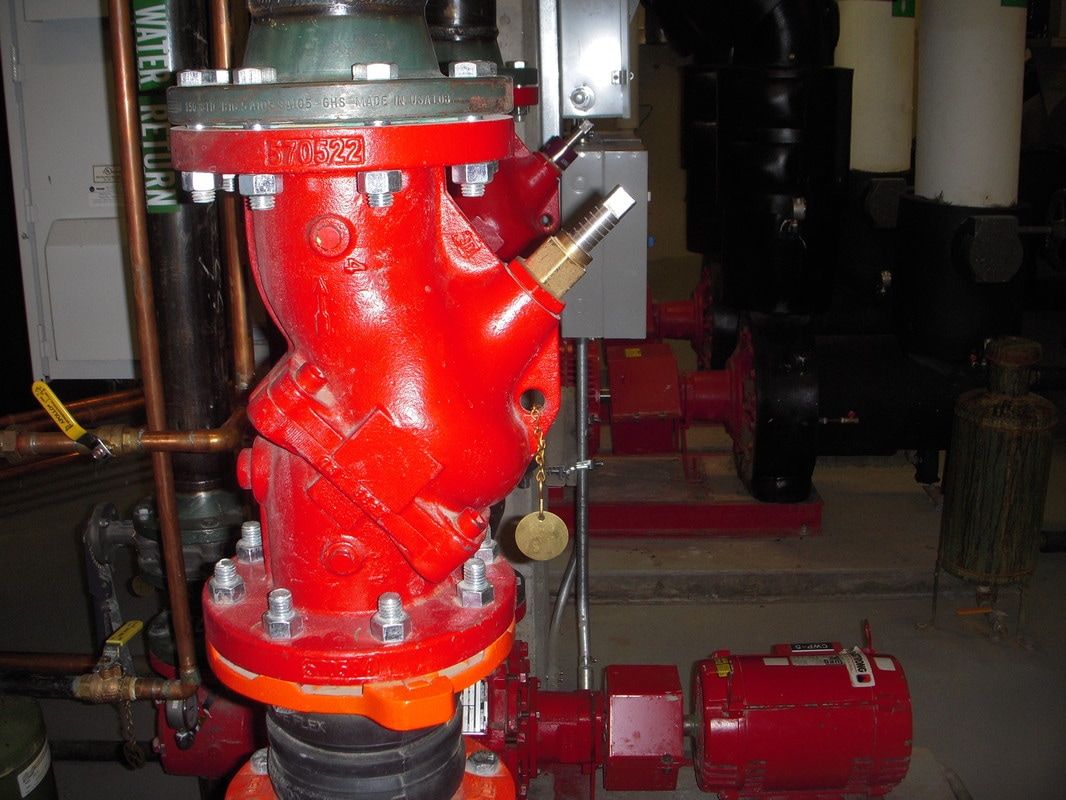

A Combination Service Valve, Check Valve and Throttling Valve

A Common Drawing Symbol for a Combination Valve

|

Service ValvesService valves are used to isolate equipment or other valve types from the system that they serve so that repairs can be made or maintenance performed. For instance, a chiller will usually have service valves on its inlet and outlet connections so you can isolate the various tube bundles from the piping system to clean the tubes with out having to drain the entire system.

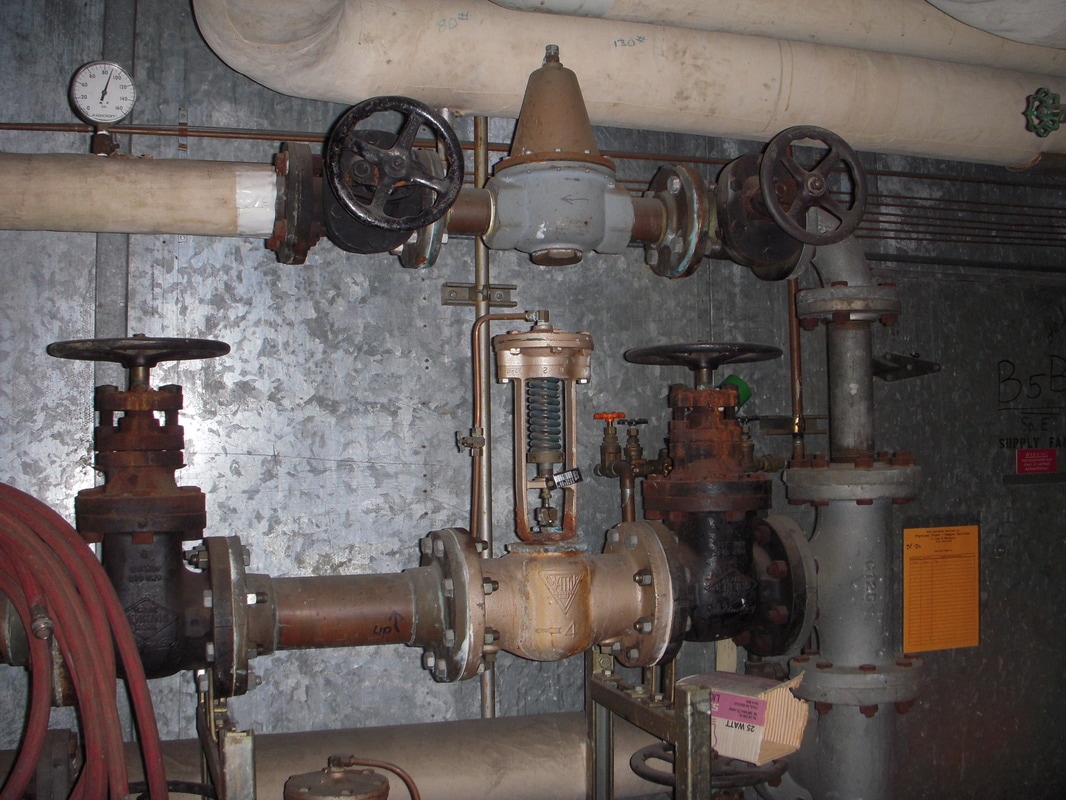

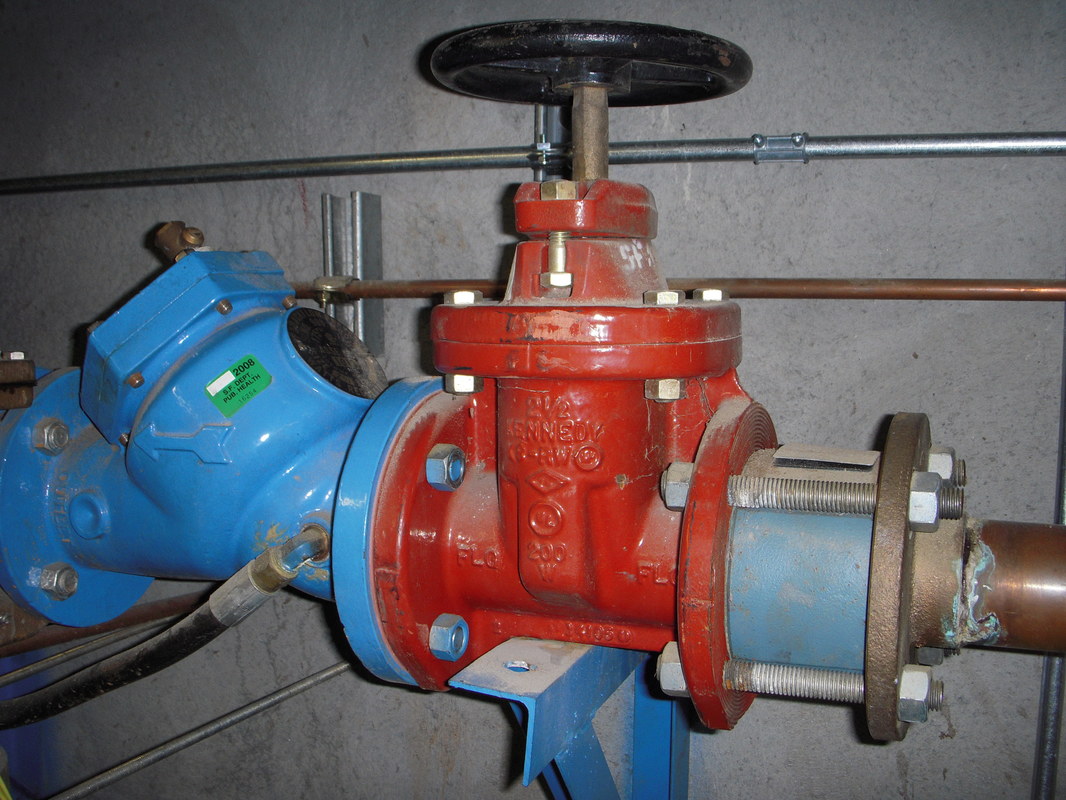

In the picture to the right, the bronze colored pressure regulating/pressure reducing valves have gate valves on each side of them to allow the pressure reducing/regulating valves to be isolated from the system for service and repair. Service valves are intended to be either fully open or fully closed and are not intended to regulate flow. In fact if you try to regulate flow with some types of service valves, like a gate valve for instance, you will eventually damage the valve seat and it will no longer be able to provide the desired isolation function. In contrast, most flow regulating valves can also act as service valves if they are completely closed, all though some of them might not be rated "bubble tight" and thus, would exhibit a minor amount of leakage if being used as a service valves (generally drips, not a stream of water). |

Gate Valves (theBlack Items) Being Used as Service Valves for Pressure Reducing/Pressure Regulating Valves (Bronze and Bronze/Gray Colored Items)

Drawing systems for Common Service Valves; A Gate Valve (Left), a Butterfly Valve (Middle) and a Ball Valve (Right)

|

|

|

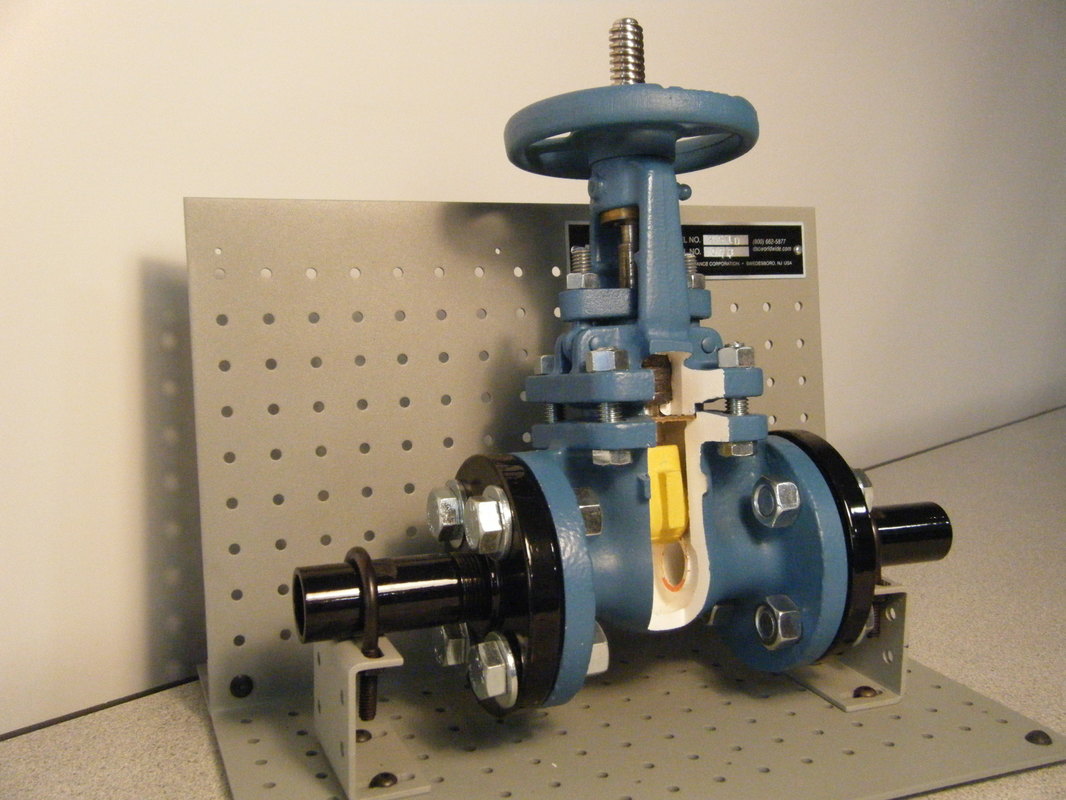

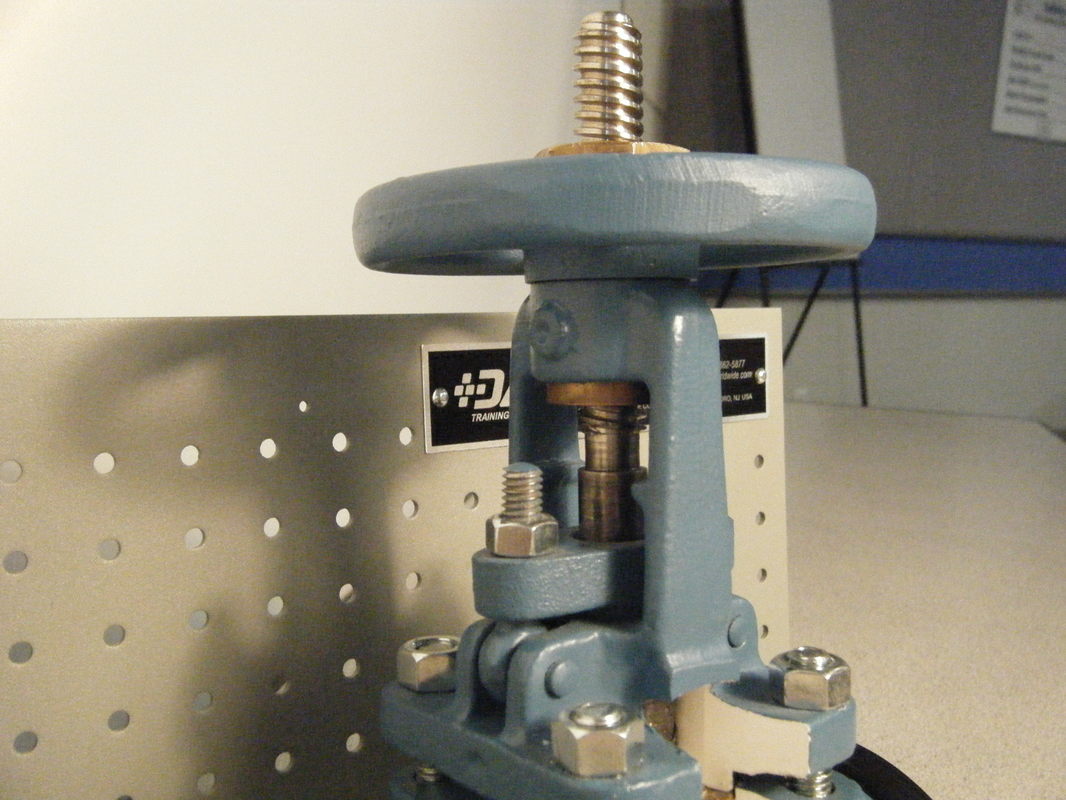

Gate ValvesThe picture to the right a gate valve that has been cut-away to reveal its internal parts. I should mention this picture and the other cut-away valve pictures on this page were taken using training samples generously provided by Ryan Stroupe of the Pacific Energy Center.

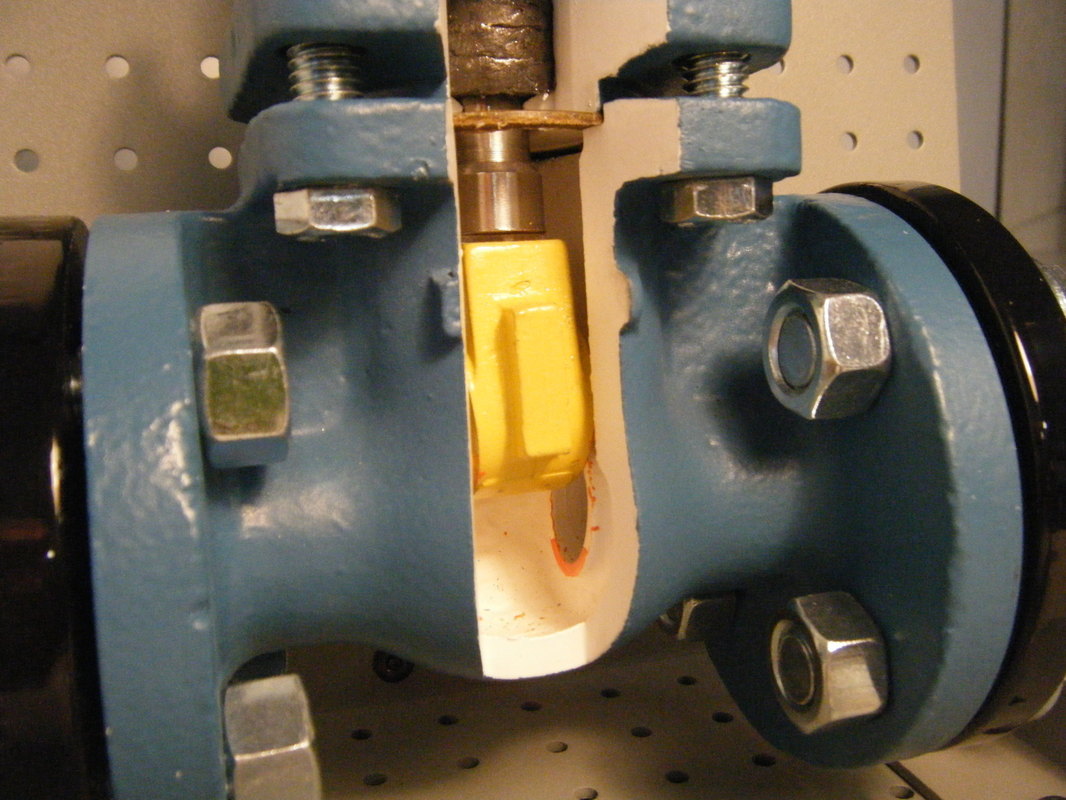

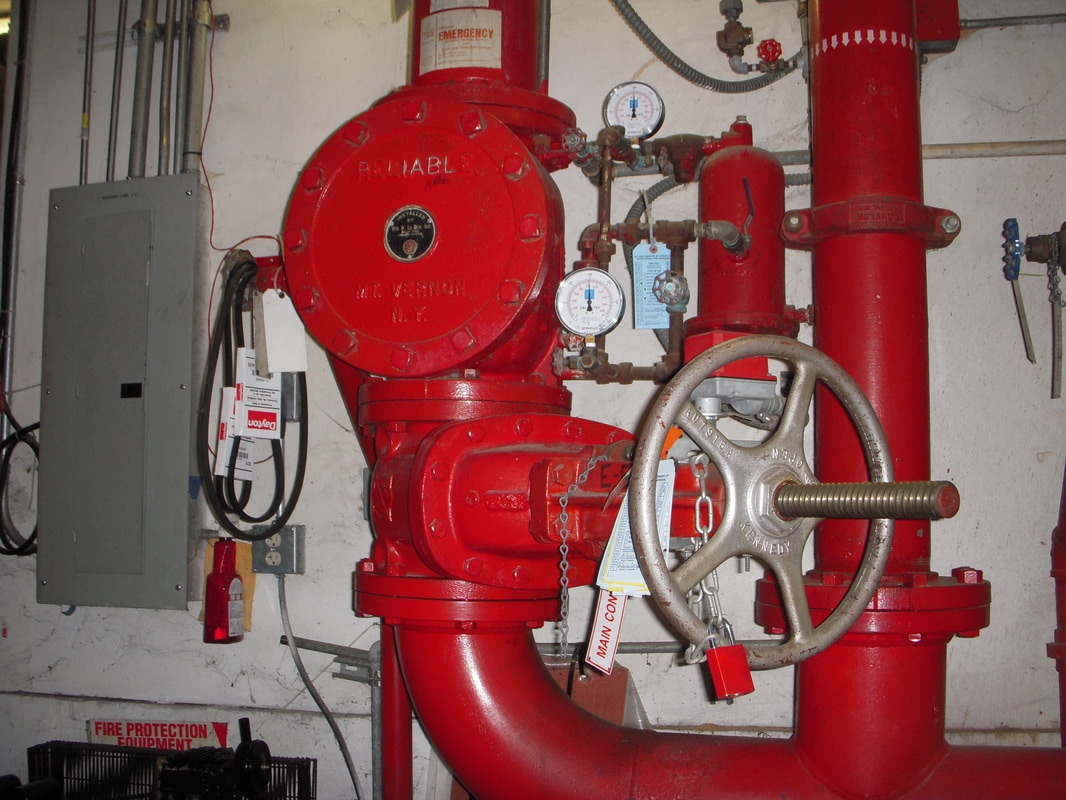

As you can see from the close-up pictures that follow, the working mechanism of the valve (the yellow part) is literally a gate that moves up and down as you turn the valve handle. When the valve is fully open, there is a "clean shot" for the fluid to flow through it with virtually no pressure drop, as can be seen from the left smaller picture below the cut-away. As you close the valve, the gate moves across the opening in the valve, as you can see from the right smaller picture, until the passage is completely closed off. Gate valves are only intended to operate fully open or fully closed. If you try to use one only partially open to regulate flow, the high velocities generated by the flow passing under the partially opened gate will erode it. When that happens, the valve will no longer close and becomes somewhat useless in terms of isolating equipment. This particular valve is called a rising stem valve because as you open it, the valve stem literally rises up out of the valve hand-wheel. This can be a desirable feature because it gives you a positive indication that the valve is actually open (assuming the gate has not come of the stem, which has been known to happen). Because of this, fire protection systems make frequent use of this type of valve and will typically have a switch monitoring the valve stem so a trouble alarm can be generated if the valve is in the wrong position, potentially compromising the ability of the system to suppress a fire where one to occur. If you look closely at some of the pictures of the fire pumps in the "Pumps" section, you can see the switches and the extended stems on the open valves. Note that there are also gate valve designs where the stem does not rise as you open the valve, Rather, the gate rides up the stem as you turn the valve wheel. This particular type of valve is also called and overhead steam and yoke valve (often abbreviated OS&Y) due to the design of the mechanism supporting the valve stem and packing. In the close-up below the two smaller pictures, the horizontal part about one third of the way up the valve stem is the packing gland. As you tighten the nuts associated with it, the packing gland compresses a seal around the stem which keeps the fluid inside the valve from leaking out. |

The video clip above illustrates what happens as you open and close a rising stem gate valve. The other images below are examples of gate valves applied out in the field.